FLEXSolar - Flexible energy

harvesting film for stand-alone microsystems

PTDC/EEA-ELC/114713/2009, 82.867€, 01-03-2011 – 31-08-2014

This

work is funded by FEDER through COMPETE funds and FCT funds in the project

PTDC/EEA-ELC/114713/2009.

The increasing

energy demand of battery-powered wireless devices requires new energy

scavenging systems, capable of harvesting energy from environment when

available and deliver it when necessary. Energy scavenging is mainly based

on thermoelectrics, vibration and photovoltaic

energy sources. In a photovoltaic scavenger, the output current and power of

the photovoltaic cells vary much as function of illumination intensity and spectra

and an energy-efficient electrical power supply from this source is difficult

to obtain under the strongly varying conditions of illumination. On the other

hand, the usual backup batteries provide voltages which decrease during

discharging of the battery. During charging, the applied voltage should also be

adapted to the evolution of the electrical potential and the stored charge. An

efficient energy scavenging system is proposed to overcome these limitations.

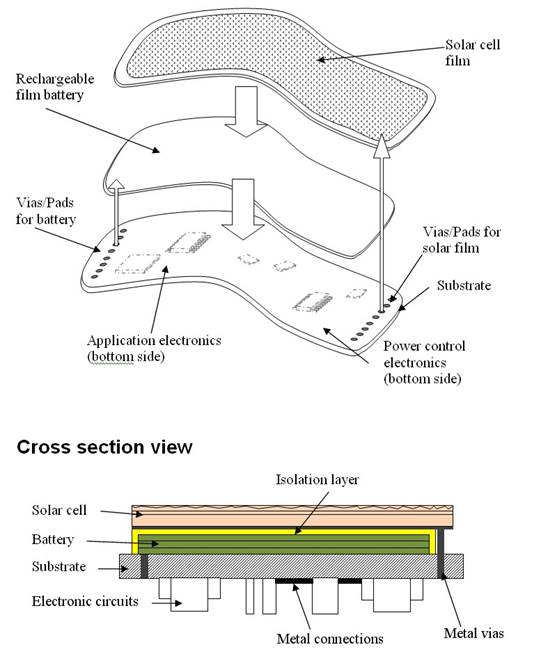

We propose a new approach offering an autonomous power source: a flexible thin

film device for photovoltaic (PV) energy scavenging that integrates a solar

cell, a lithium battery and electronics for maximum power point tracking (MPPT)

and battery charge. This flexible thin film stack (see annexed figure) can be

used in sensing and monitoring applications, in particular human body

applications. The device is flexible enough to be applied on a curved surface

like the human body and supply energy for autonomous wireless microsystems,

which can also be integrated in the film. The film is composed of three parts:

• A flexible

thin-film photovoltaic cell.

• A flexible

rechargeable solid-state lithium battery, fabricated by planar thin-film

technology.

• A flexible

surface-mount (SMD) electronic circuit, for DC-DC conversion and power

management that can also include application electronics for monitoring

purposes.

The inclusion of a

thin-film battery in the system adds the possibility of powering the device

when light is not available. Since many of wireless sensors are powered in a

peak basis, the battery can supply this current. Electronics and materials

engineering are involved in this project. Considering materials engineering,

two main research areas are considered: Thin-film Si photovoltaic cells and

solid-state lithium rechargeable batteries.

The main key

challenges in each area are:

• Fabrication of

thin-film Si photovoltaic cells on flexible substrates, with efficiency higher

than 5%

• Fabrication of

flexible solid-state rechargeable batteries with fast charging-time. A layered

lithium battery is proposed to decrease charge time and decrease capacity of

conventional solid-state lithium batteries.

• Electronic

circuits to charge battery with maximum efficiency using MPPT algorithm,

considering the voltage and current supplied by photovoltaic cell and provide

power (in a peak basis) and information about remaining battery charge to

application electronics.

The target

properties of this device are:

• Area of 10 cm2.

• Thickness below

2 mm of the whole film including electronic circuits.

• Unlimited number

of bending actions over a curved surface with a radius of 20 mm.

• Highly flexible

amorphous silicon-based photovoltaic cells with AM 1.5 conversion efficiency

above 5% and fill factor of 0.65.

• Battery voltage

of 4.2 V and capacity of 5 mAh,

corresponding to 0.5 mAh/cm2.

• Charge and

discharge rates up to 5C.

• Electrolyte

materials with an ionic conductivity of 2 × 10-6 S/cm at room temperature.

• Dynamic

optimization of the voltages and currents of photovoltaic cell harvesting and

battery charging.

• Supply voltage

available for the electronic application 3.3 V.

• Electrical power

conversion efficiency of 90% in average from the solar cells to the battery and

95% from battery to application electronics.

• Power management

unit uses the direct battery voltage.

• Charging time of

full battery capacity in less than 15 minutes, under direct sunlight.

An efficient energy scavenging system was proposed, offering an autonomous

power source: a flexible thin film device for photovoltaic (PV) energy

scavenging that integrates a solar cell, a lithium battery and electronics for

maximum power point tracking (MPPT) and battery charge. The film is composed of

three parts:

• A flexible thin-film photovoltaic cell.

• A flexible rechargeable solid-state lithium battery, fabricated by planar

thin-film technology.

• A flexible surface-mount (SMD) electronic circuit, for DC-DC conversion and

power management that can also include application electronics for monitoring

purposes.

• A flexible thin-film photovoltaic cell, not developed, but bought in the

market, as suggested by project evaluators.

• A flexible rechargeable solid-state lithium battery, fabricated by planar

thin-film technology

• A flexible surface-mount (SMD) electronic circuit, for DC-DC conversion and

power management that can also include application electronics for monitoring

purposes.

The achieved properties of this device are (described here in the same

order of proposed properties):

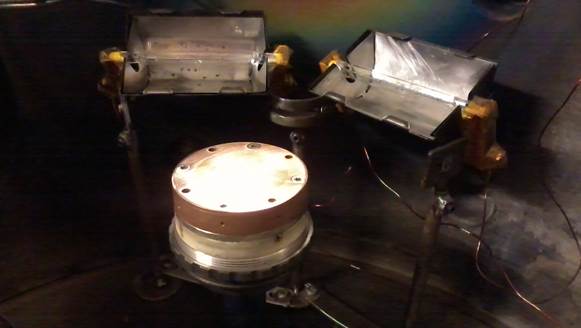

• Area of 1 cm2. (10cm2 was proposed. With equipment available, uniformity of

films could not be achieved in larger areas. However, the fabrication process

for a 10cm2 device would be the same, using larger area sputtering equipment

(Figure 6).

• Thickness of 1.6 mm of the whole prototype film including electronic

circuits. (bellow 2mm proposed). Fig 3

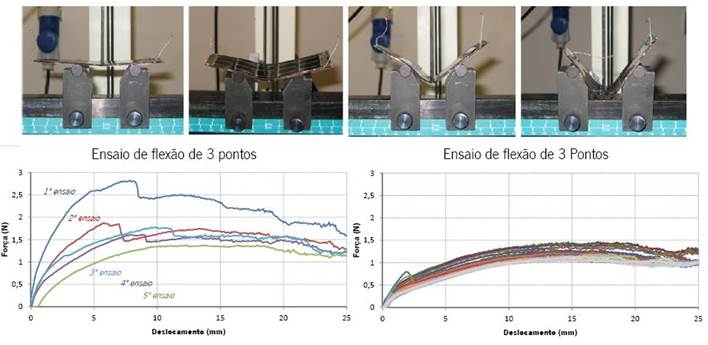

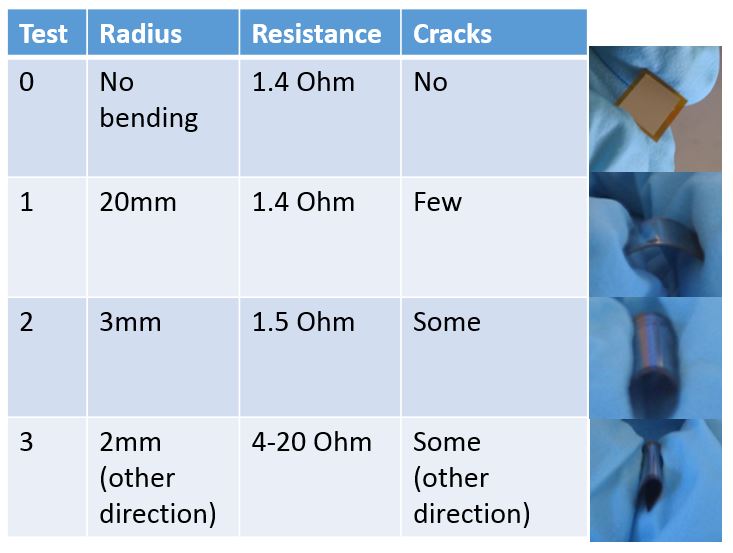

• Unlimited number of bending actions over a curved surface with a radius of 20

mm in the complete prototype. Radius bellow 5mm was achieved in battery film.

[P1], Fig 8 and Fig 9

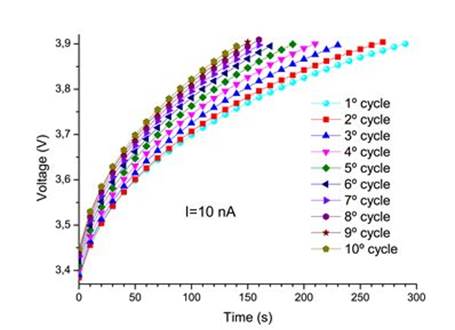

• Battery voltage of 4.2 V and capacity of 10.8nA/cm2. [C1]

The smaller value of capacity is due to low thickness of films and

insufficient crystallization of cathode film. Higher capacity can be obtained

in thicker films (resulting in a longer fabrication process). Also was reported

that annealing at temperatures of 600-700 ºC results in crystalline films [P3].

This was achieved in this project using silicon substrates this process was not

compatible with flexible substrates used. Efforts are still being made to get

higher crystallization using Pulsed Laser Techniques, in a collaboration with Vigo University.

• Charge and discharge rates up to 6C. Charge from 3.4V to 3.9V in less

than 150-300 seconds. [C1]

• Electrolyte materials with an ionic conductivity bellow 2 × 10-6 S/cm at room

temperature. [P2]

• Dynamic optimization of the voltages and currents of photovoltaic cell harvesting

and battery charging. [P1, T3, T4]

• Battery voltage available for the electronic application. A fixed voltage of

3.3V was proposed, and could be obtained with an additional DC-DC converter,

but efficiency would decrease. Since the battery voltage 3.4 to 4.2V is

acceptable for a large variety of circuits, this extra DC-DC converter was not

developed.

• Electrical power conversion efficiency of 85% in average from the solar cells

to the battery. MPPT control starts with

very low light conditions, bellow 6Wm2 [P1], and voltages as low as 250mV.

• Electrical power conversion efficiency above 95% from battery to

application electronics. Internal

resistance (Battery to electronic circuit) bellow 5 Ohm and typical operating

current of 550nA. Low Battery disconnect function to protect battery from

over-discharge (<0.1nA). [T2].

• Power management unit uses the direct battery voltage.

• Charging time of battery bellow 6 minutes in the thin-film fabricated

battery. [C1]

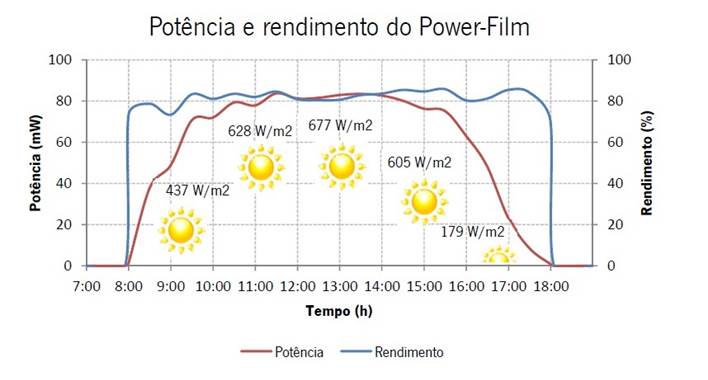

Fig1: Power-film power and efficiency during a day

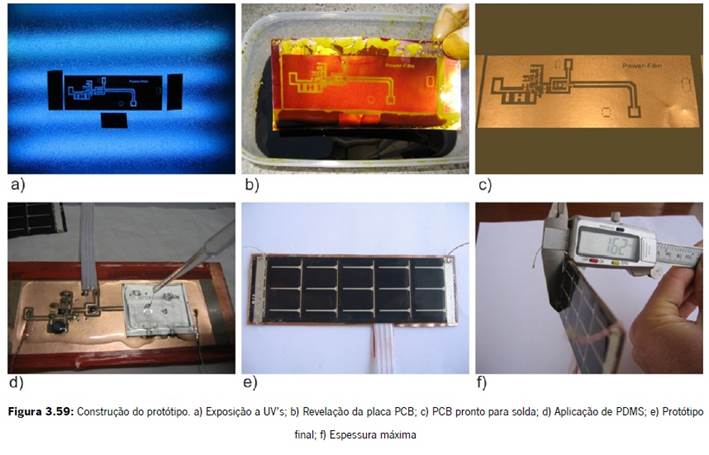

Fig3: Power-film prototype fabrication

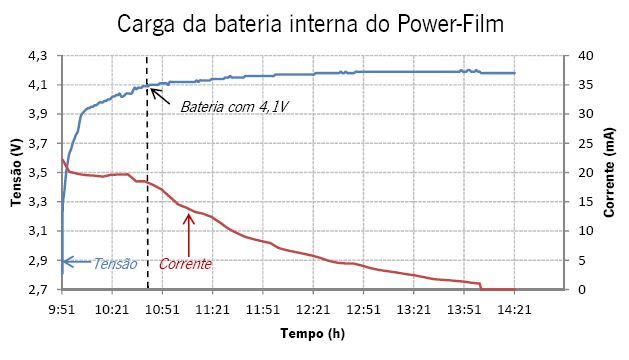

Fig4: Power-film prototype charging in a real situation

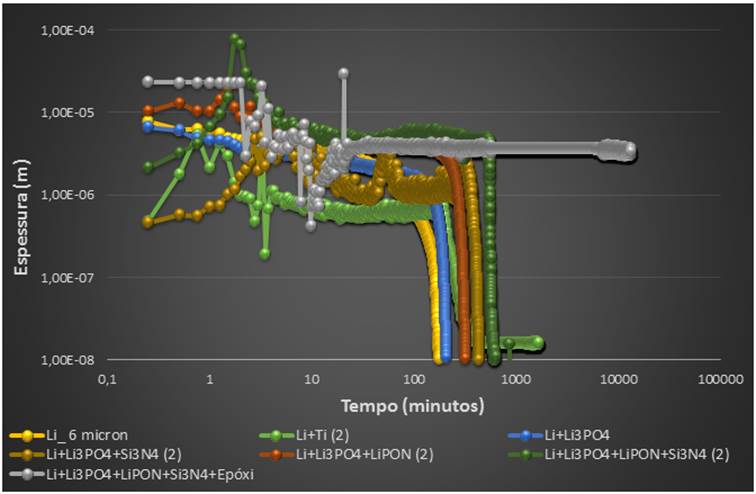

Fig5: Battery protection. Thickness of battery film not oxidized during

exposition to air.

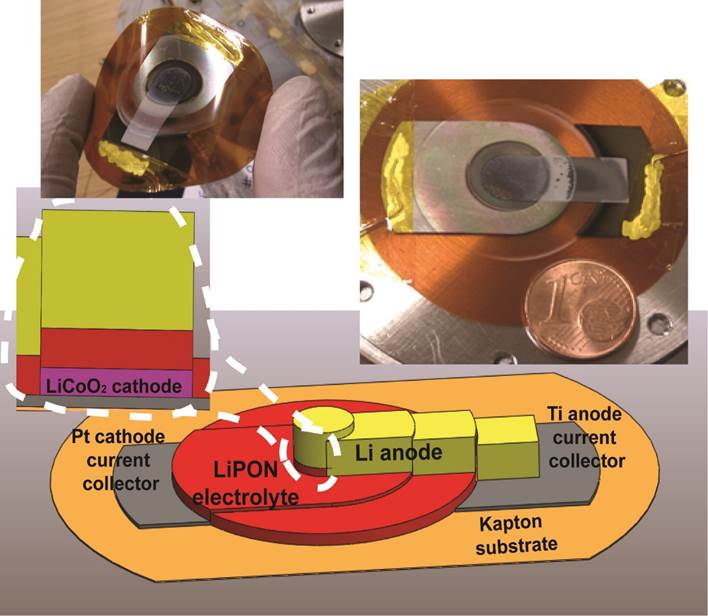

Fig6: Fabricated battery

Fig7: Charge/discharge curves of fabricated battery

Fig8: Prototype flexibility test

Fig9: Films flexibility test

Books

(chapt)

[L1] M. F. Silva,

J. F. Ribeiro, J. P. Carmo, L. M. Gonçalves, M. M. Silva, and J. H. Correia,

Solid state thin films lithium batteries for integration in microsystems, Book

Chapter for the upcoming issue Scanning Probe Microscopy in Nanoscience

and Nanotechnology 3. Springer, ISBN 978-3642254130, 2012

Journal

[P1]

JP Carmo, JM Gomes, LM Gonçalves, JH Correia; A flexible thin-film for powering stand alone

electronic devices, Measurement

46 (10), 4145-4151

[P2] J. F. Ribeiro,

R. Sousa, J. P. Carmo, L. M. Gonçalves, M. F. Silva, M. M. Silva, and J. H.

Correia, “Enhanced solid state

electrolytes made of lithium phosphorous oxynitride

films”, Thin Solid Films, 522,

85-89.

[P3] J.F.

Ribeiro, R. Sousa, M.F. Silva, L.M. Goncalves, M.M. Silva and J.H.

Correia, “Thin-film Materials for

Solid-State Rechargeable Lithium Batteries”,

ECS Transactions, Electrochemical Society, Vol. 45 (29), pp. 139-142, April

2013.

[P4] Ribeiro, J. F.; Sousa,

R.; Sousa, J. A.; Pereira, B. M.; Silva, M. F.; Gonçalves, L. M.; Silva, M. M.;

Correia, J.H., "Rechargeable lithium film batteries: encapsulation and

protection", Procedia Engineering, 47, 676-679,

2012.

Conferences

[C1] J.F. Ribeiro, R. Sousa, J.A.

Sousa, L.M. Goncalves, M.M. Silva, L. Dupont and

J.H. Correia, “Flexible Thin-Film

Rechargeable Lithium Batteries”, Transducers2013, Barcelona, Spain, June

16-20, 2013.

[C2] J.F. Ribeiro, R. Sousa, L.M. Goncalves,

M.M. Silva, L. Dupont and J.H. Correia, "Lithium cobalt oxide deposited on polyimide

substrate", 13th European Vacuum Congress (EVC13), Aveiro,

Portugal, September, 2014.

[C3] J.F. Ribeiro, R. Sousa, J.A. Sousa,

L.M. Goncalves, M.M. Silva, L. Dupont and

J.H. Correia, “Thin-Film Lithium

Batteries Materials”, Vacuum2013, Paris, France, September 09-13, 2013.

[C4] R. Sousa, J.F. Ribeiro, J.A. Sousa,

R.T. Montenegro, L.M. Goncalves and J.H. Correia, “Silicon nitride thin-films by RF sputtering: application on solid state

lithium batteries”, MME2013, Hanasaari, Finland,

September 1-4, 2013.

[C5] R. Sousa, J.F. Ribeiro, J.A. Sousa,

L.M. Goncalves, J.H. Correia, “All-solid-state

batteries: an overview for bio applications”, Bioengineering 2013, Braga, Portugal, February 20‑23,

2013.

[C6] Ribeiro, J. F., Sousa, R.,

Sousa, J. A., Pereira, B. M., Silva, M. F., Goncalves, L. M; Correia, J. H. “Rechargeable lithium film batteries–encapsulation and

protection”,. Eurosensors

2012, Krakow, Poland, September 9-12, 2012

[C7] J.F.

Ribeiro, Rui Sousa, J.A. Sousa, B.M. Pereira, M.F. Silva, L.M. Goncalves, M.M.

Silva and J.H. Correia, “Encapsulation

of Rechargeable Solid-State Lithium Batteries”, 222nd ECS Meeting(PRIME),

Honolulu, Hawaii, USA, 2012.

[C8] J. F.

Ribeiro, M. F. Silva, L. M. Goncalves, M. M. Silva, J. P. Carmo and J. H.

Correia, “Layered materials for solid-state rechargeable lithium batteries”,

221st ECS Meeting, Seattle, USA, May 6-10 2012.

[C9] J. C.

Ribeiro, M. F. Silva, J. F. Ribeiro, L. M. Goncalves, J. P. Carmo, J. H.

Correia, M. M. Silva, F. Cerqueira, P. Alpuim, J.-E. Bourée, “Thin-film solid-state rechargeable lithium

battery”, Proceedings of MME 2011, pp. 190-193, Toensberg,

Norway, 19-22 June 2011

[C10]

J. F. Ribeiro, M. F. Silva, L. M. Goncalves, J.P. Carmo, J. H. Correia,

“Thin-film improved materials for solid-state lithium batteries”, Proc. of

Materials 2011, pp.1, Guimaraes, Portugal, 18-20

April 2011.

Finished Mscs

[T1] MscThesis Sensores sem fios autónomos,

alimentados por painel solar e microbateria de lítio, com controlo de alimentação

através de circuitos MPPT de baixa potência, Avelino Araújo Ferreira, MIEEIC,

Início 1-11-2010 fim Dez2012

[T2] MscThesis Power-Film:

Um filme flexível autónomo para alimentar dispositivos elétricos, José Miguel

Sousa Gomes, Mestrado Integrado em engenharia electrónica

e de computadores da UM, 01-11-2010 a 2-05-2012

[T3] MscThesis “Conversor DC-DC em tecnologia CMOS

para energy harvesting”,

Mestrado Integrado em engenharia biomédica, Fernanda Guedes, Out 2011-Out 2013

[T4] MscThesis Implementação de um sistema MPPT, em

circuito integrado CMOS, Nilton César Lima Lopes, MIEEIC, Início 1-11-2011 -

2013

[T5] MscThesis Bateria de lítio em

filme fino - Fabrico e caracterização de novos materiais para utilização no

ânodo, José Augusto Fonseca de Sousa, MIEIC, Início 1-11-2011-2012

[T6] MscThesis Bateria de lítio em filme fino –

Fabrico e caracterização do cátodo em substrato flexível, Rui Pedro Pereira da

Costa, MIEEIC, Início 1-11-2011- 27/12/2013

[T7] MscThesis Proteção de uma

bateria de lítio em filme fino, Bruno Miguel Oliveira Pereira, MIEEIC, Início

1-11-2011-2012

New Equipment

Magnetrão TORUS 2HV, AXIAL MNT, 10"TUBE, STD Magnet assy, Swing shutter

Exterior

da câmara (esq) e magnetrão no interior da câmara de

deposição (dir)

Equipamento

para posicionamento e aquecimento de substrato em camara de deposição

(no

interior da câmara de deposição)

Sistema com sensor para medição do oxigénio,

IONIC SYSTEMS GMBH

Este trabalho é financiado por Fundos FEDER

através do Programa Operacional Factores de Competitividade – COMPETE e por

Fundos Nacionais através da FCT – Fundação para a Ciência e a Tecnologia no

âmbito do projeto PTDC/EEA-ELC/114713/2009.